Looking back, I can say for sure that I have learned much that I did not know before from this module as a whole. The bridge designing process, from the initial stage to the final, is overall much more in depth and complicated than I had ever imagined. From the past ten weeks, I have learned about different kinds of bridges, how bridges work, why they are important, and most importantly how they are finally built. I have also learned some of the basic math behind the magical force dispersing properties of the truss system of construction. Overall, I am much more generally aware of the design process as an engineer from this module.

The least beneficial aspect of this course was probably the lack of variety in the weekly work we were required to complete. Every week it was the same: lecture/build in lab, then blog post. With a longer post due every other week or so. While this was not a huge issue, the basic busy work just was not beneficial to my experience.

On the other hand, though, the most beneficial experience was the teamwork I witnessed and was a part of throughout the process. My team completed everything required of us and still came in second place, making me very excited and proud. I now understand why professor Mitchell put such an emphasis on teamwork in the beginning of the course. It truly is one of the most important aspects of being an engineer; working with other engineers.

Overall I learned very much through the requirements of this course and would recommend either keeping it in engr 103 or adding it to engr 102 as an option.

Wednesday, June 6, 2012

A4- Greenwood, Carr, Banyas

Final Report - Assignment 4

John Greenwood, Kevin Carr, Jordan Banyas

Bridges have been and will always be a stunning reminder of human

ingenuity. The ability to cross large expanses or bodies of water

without flying is one of the most useful creations mankind has ever

imagined. Modern bridges have become much more advanced due to

increasing needs in many areas. These areas include, but are not

limited to, safety, aesthetics, and cost-effectiveness. Therefore,

the goal of this engineering 103 module was to imagine, design, and

ultimately create the most efficient and safe bridge among

competitors. In order to accomplish this task, weeks of planning and

teamwork were required to build a bridge using K-nex building pieces.

The bridge would then be tested, spanning a 36 inch gap and holding

a bucket which would hold an increasing amount of sand. The bridge

team that calls itself “Three Pikes on a Bridge” created and met

all of the specific building requirements, and eventually held 58.6

pounds. Closer inspection of the creation would reveal that it was a

truss bridge. Trusses are the most common method of building strength

between members in a bridge. Basically, a truss is a series of

triangles formed by the beams, or members, in a structure. A

triangle is the strongest possible shape to arrange these members in;

therefore, trusses disperse the force between them almost perfectly

when arranged correctly.

At

the beginning of the term, “Three Pikes on a Bridge” had one goal

and one goal only; to construct the most cost efficient bridge.

Throughout the course of the class the determination did not waiver,

as useful information was provided along the way. West Point Bridge

Design (WPBD) was the first tool introduced during the bridge

building process. This helped greatly, as it was a basic introduction

to the bridge building experience. Through WPBD a multitude of

lessons were learned. The first lesson was how to create a successful

bridge. To accomplish such a task the weight of the bridge itself

must be taken into consideration. In addition, the group learned that

the simplest design can be the best design for it uses the least

number of pieces. Finally, this program conveyed the message that a

plethora of tests of many designs leads to a polished and effective

one. After the WPBD assignment was completed, the group began to

eagerly work with the K-nex in preparation for the first bridge

design competition.

.JPG) |

| Figure 1- Original Bridge Design |

During the first bridge design competition,

the constraints were clearly presented. The Bridge had to span two

feet and be a minimum of three inches wide. Attached above is a

picture of our first bridge (figure 1). It was found to have

tremendous vertical strength, but the sheer tension snapped the

bridge once the weight exceeded seventeen pounds. Due to the way the

bridge broke, the group felt as though the bridge needed stronger

cross braces to hold it steady while weight was being applied.

Throughout the course of the class from week to week the members

tried different support structures. The group suffered many

disappointments of initial high expectations. Once the truss analysis

assignment was given, the group quickly realized the reoccurring

problem. To add strength to the bridge, it needed to be taller. At

this point, the vertical force would be dispersed over a greater

area, thus being able to hold more weight. Thankfully this discovery

was made just in time to help the group perform exceptionally in the

competition.

Through trial and error, the group found the strongest design for the side of the bridge to be an X-shaped structure. This utilized the blue two-inch pieces held together by the 360-degree white gusset-plates. To handle the sheer tension factor, red five inch pieces were used in a zigzag like pattern and held together by two blue 360 degree gusset-plate pieces. These gusset-plates were also oriented to connect the bottom of the bridge with the next layer of the bridge. They held yellow three inch pieces together. The end of the bridge was the only part that was not free standing; therefore, most of the force would be imposed on the ends. Due to this, extreme precautions were taken during the construction of the ends. The group utilized the small one inch pieces combined with the yellow 180 degree connectors. Once this portion was built, the group decided it would be an excellent idea to add a second truss on top of the original. The second layer was much like the first except the 360 degree gusset-plates were oriented differently. Such a difference was the orientation of the red five inch piece trusses. Formerly in a zigzag fashion, the pieces were then connected diagonally in an alternating fashion. A picture of the final bridge has been attached below (figure 2). Overall, 369 pieces were used during the construction of the final bridge which cost 520,000 dollars and held 58.6 pounds. This means the bridge had a cost to weight ratio of 8,873.72 dollars per pound.

Through trial and error, the group found the strongest design for the side of the bridge to be an X-shaped structure. This utilized the blue two-inch pieces held together by the 360-degree white gusset-plates. To handle the sheer tension factor, red five inch pieces were used in a zigzag like pattern and held together by two blue 360 degree gusset-plate pieces. These gusset-plates were also oriented to connect the bottom of the bridge with the next layer of the bridge. They held yellow three inch pieces together. The end of the bridge was the only part that was not free standing; therefore, most of the force would be imposed on the ends. Due to this, extreme precautions were taken during the construction of the ends. The group utilized the small one inch pieces combined with the yellow 180 degree connectors. Once this portion was built, the group decided it would be an excellent idea to add a second truss on top of the original. The second layer was much like the first except the 360 degree gusset-plates were oriented differently. Such a difference was the orientation of the red five inch piece trusses. Formerly in a zigzag fashion, the pieces were then connected diagonally in an alternating fashion. A picture of the final bridge has been attached below (figure 2). Overall, 369 pieces were used during the construction of the final bridge which cost 520,000 dollars and held 58.6 pounds. This means the bridge had a cost to weight ratio of 8,873.72 dollars per pound.

.JPG) |

| Figure 2 - Final Bridge Design |

Upon

testing the completed bridge, which met every requirement and

standard of the module, the bridge exceeded initial predictions of a

45 pound failure load by a whopping 13.6 pounds. The load of 58.6

pounds was the breaking point of the truss. Sadly, the completed

design came short of the group’s goal by about 300 dollars per

pound. Three Pikes on a Bridge’s final creation placed as the

second lowest cost per pound held among the class. When the point of

failure was inspected more closely, it was discovered that the actual

failure mode occurred in one of the lower members about 2/3 across

the bridge. This may have been due to any number of problems,

including loose gusset plates or an off-angle point of loading.

Regardless of the point of failure, the group considered the bridge a

great success.

After

many tests and revisions to the design, this bridge performed in ways

that were unexpected. One of the main performances that shocked the

group was the amount of load that it held. It was collectively

estimated that the bridge would hold close to 45 pounds. However,

the truss actually exceeded this estimate quite significantly,

holding 58.6 pounds. In addition to the load carried, one of the

other things that contradicted with predictions was the failure point

of the truss. The agreed position of failure was the end of the

truss for it was constructed on an angle and the force was dispersed

to one point. It was believed that the force of the load would

separate the member from the piece that rested on the stand. The

actual failure point was the middle of the truss. In summation, the

truss split in half. It was concluded that the truss was very rigid

and had a well-balanced dispersion of forces. In contrary to the

group's false estimates there was one thing that was parallel to

predictions. This happened to be the way of failure. It was

established that the truss would not fail gracefully and it did not.

It happened to be a quick and violent failure. This was due to the

rigidity of the members and structure of the overall design. The

group was extremely satisfied with the bridge's performance for it

found a spot at second place for the section.

Although

the performance of the truss proved to be very successful, there are

potential revisions that could have been made. If given another

chance, some design alteration would include increasing the height of

the truss. By doubling the height of the truss, the load held more

than doubled from previous tests. The most contributing factor to

such improvement was the vertical dispersion of forces. Therefore, a

potential addition would be a truss below the resting point. This

increase of vertical span would prove to be quite affective for

designs. Moreover, one mistake made was the orientation of the board

on the bridge. It was perpendicular to the truss and had a lot of

focus on the center. If given another chance the long side of the

board would be oriented parallel to the long span of the truss. It

would lead to a more even dispersion of forces and would yield a

higher carrying capacity. To greater enforce this change the group

would also change the gusset plates to make a flat surface for the

plate to lie down. This would ensure a sturdy base and minimal

chance for slipping or uneven placement.

Tuesday, June 5, 2012

Week 10 Blog Post

This term has taught me many things regarding bridge design. One of the main things is that I learned the importance of triangles in a design. I will never forget their importance. Moreover, I value the fact that I now know truss analysis and multiple tests lead to a stronger and more efficient truss. These were the most beneficial lessons on the course. Trial and error is key. One thing that I found to be the strongest aspect of this course was the application of WPBD. This program allowed a significant number of tests in a short amount of time. The computer generation proved to be very useful in the design process. The weakest part of this course was the application of a blog. It was least beneficial to me. I believe that the engineering notebooks would have been just as effective. Moreover, this would enable better designed bridges due to the grid lines. One final thing I learned is that the height of a bridge greatly strengthens it. The vertical dispersion of forces proved to be extremely helpful in creating a strong truss.

Week 10 blog Post Jordan Banyas

Overall this class was developed to further our understanding of truss analysis, support structures, and bridge building in general. That being said, I believe through this class I now have a much better understanding in all three categories. However, every class has it's ups and downs. The only main complaint I have about my experience in bridge building was that we spent too much time with West Point Bridge Design. Although that helped us understand how bridges worked and how to make the best support structure in that given technology, it did not help us with our over all project of building a bridge that much simply because the forces imposed upon the WPBD bridge was completely different then that of which we exerted on the K-NEX bridge. I think if you were to shorten that section of the class and use that time to teach about truss and joint analysis, the time would be better served. The most beneficial part of this class in my mind was the trial and error period. From week to week my group members and I would come up with a completely new bridge design and test it, record it's strengths and weaknesses, and figure out a way to make it better. Through this we were able to learn a multitude of different ways to improve our support structure. Our hard work came to fruition when our group built the most efficient bridge (or at least most efficient bridge that followed all of the constraints) during last weeks final testing period.

Wednesday, May 30, 2012

week 8 blog post Jordan Banyas

Through our bridge designing process, we learned that the way to add strength to your bridge is to add height to it. This helps disperse the vertical forces more effectively. This week we re-designed our bridge's truss system as well as adding a new top layer. Our final design includes 369 pieces and costs 520,000 dollars. we hope it will hold around 45-50 pounds.

What I learned

Throughout the term, each of our individual designs changed quite significantly. The main reason for our changes was because of failure from testing. I believe that the testing portion of the design process is the most important step for it gives us the most information. Some of the information given are failure points, durability, a transfer of forces. With this data, our group was able to formulate a very effective truss. Some specific design hints were that the design should have a large height in order to evenly distribute the force across more member. This was derives through many tests. Testing yields very helpful knowledge.

Wednesday, May 23, 2012

Greenwood - Week 8

At this point we have discovered force in truss members using the Joint Method form of analysis. It was an easy enough approach to the problem of force in long members on real bridges, and I believe it can be applied into real applications. For example our Knex bridge can and should be analyzed mathematically before we attempt to apply any extraneous weight to it. Actual engineers use math as a tool everyday to make sure their ideas can come to life, and we are no different. Safety, usefulness, and financial awareness are all issues which can be addressed using simple math and physics. If a bridge breaks due to a problem that could have been foreseen using a pencil and paper, there is no excuse for this laziness.

Down the line I believe I would like to analyze some of the factors which contribute to the swaying of the bridges we have seen in lab. It obviously is an issue with the joints of the trusses, but there must be a way to look at these problems on paper before we apply them in lab. It seems that Knex joints are not very strong, but that should not matter with a proper design. This week and next week our group will be working hard to look at our bridge very closely to analyze any problem we may foresee.

Down the line I believe I would like to analyze some of the factors which contribute to the swaying of the bridges we have seen in lab. It obviously is an issue with the joints of the trusses, but there must be a way to look at these problems on paper before we apply them in lab. It seems that Knex joints are not very strong, but that should not matter with a proper design. This week and next week our group will be working hard to look at our bridge very closely to analyze any problem we may foresee.

Tuesday, May 22, 2012

Week 8- Jordan Banyas

For the project we are doing in this class, the truss analysis information is very helpful. The truss analysis we were taught deal with static forces which is similar to what our goal is in the bridge building competition. However, for a real bridge these calculations would not be very helpful because the forces would be dynamic as opposed to static. We would have to learn a whole new method of calculations to keep up with the force enacted by a moving vehicle. At this point in the term I believe we have learned all that we need to be successful in this project. Now it just becomes a matter of putting all of our knowledge into action. This week we tinkered with out bridge a little bit more and believe we finally have a successful idea. We will further execute this idea throughout the week so we are ready for the final competition in week nine.

A3-Jordan Banyas

After doing the calculations for a bridge with a height of 6 inches,

length of 24 inches, with a weight of ten pounds imposed on it. The

calculations are shown in the picture below. This applies to our project

in that the sides of our bridge are very similar to the bridge we

calculated. Although we have not figured out the exact dimensions of it

yet, we can now accurately calculate what dimensions will give us the

best results.

Tuesday, May 15, 2012

Week 7- Carr

Last week in lab we tested one of our bridge designs and it performed fine yet we are striving for something more. We, as a group, would love to see our bridge shatter the previous weight test. Because of this, we went back to the drawing board and designed a new type of truss. We fell confident about how it will perform and can't wait to test it. Some data would be extremely helpful in our design process. The forces exerted on each member or plate would greatly aid us in determining how to better disperse forces. If we were to take this in our own hands we would change the weight into newtons and break up the forces into different directions. We would use sine and cosine to find the partial forces in different directions and mathematically design a strong truss.

Jordan Banyas week 7 post

This week we reconstructed our bridge based on the results of last week's weigh in. Our bridge held a disheartening 17.4 pounds of compression on our bridge, however we are confident we can fix the problems. Learning about how to calculate the force exerted on our outer trusses would be very useful information. Right now, based on our knowledge of the summation of forces and that each angle is at a forty-five degree angle, we can have a basic understanding as to how the forces are dispersed. By taking the cosine or sine of fourty-five and setting it equal to the amount of weight exerted on the bridge, we can successfully calculate how much force each member we will hold. The only question is how much force will it take to break our design?

Wednesday, May 9, 2012

kevin carr week 6

This week we worked on our Kinex bridge. We have a strong design but fell short on pieces. We will continue to build and improve our bridge design. We will test it today in class and improve our weak points.

Jordan banyas week 6

This week we think we have a very promising bridge design. We dropped our old idea and added cross sections to the top of our bridge to stop it from swaying when force is acted upon it. We look forward to testing the new bridge this week. This weeks goals will consist of finding our bridges less attractive points and polishing them up before we test it again.

Week 6-Greenwood

After using Knex over the past week designing and redesigning our bridge, my views have only slightly changed. The main difference between my post last week and now is that I know that WPBD and Knex are two entirely different tools. Since Knex requires us to think in 3D, WPBD really is only the first, most basic step in building a bridge.

When building an actual bridge made of steel instead of Knex, there would be no loose "joints" where the Knex is having issues staying in a rut. On a real bridge, the connectors are finals. This just means that Knex allows the group to more accurately create a working bridge model, as opposed to just putting together something that is large, expensive, and ugly. Hopefully our team can complete this task in the coming weeks, as the module draws to a close.

Thursday, May 3, 2012

A2 Greenwood

The goal of this module is to create the most cost effective, useful bridge using Knex which spans a distance of two feet. In order to accomplish this, many designs and prototypes had to be used. In this case, we have just began the transition from WPBD to using Knex, and it is very difficult. First of all, we are very limited by the cost and amount pieces/connectors we have to work with. To overcome these obstacles, we have worked hard as a team to create designs which will work. For this A2 design, I have drawn up a simple prototype which I believe could be cheap and strong.

Above is the projected price of my bridge. Although I have not actually put together my idea, I am almost positive this will increase as I find mistakes in my design.

Above is my rough sketches of my design. Basically, it is a simple truss bridge which elevate to an even high sections of trusses at the top. I believe this will add stability as well as good support for the weight apparatus. The only issue now is the price.

Wednesday, May 2, 2012

Week 5 Post- Greenwood

For the past five weeks we have been using West Point Bridge Designer as our groups main tool for creating prototype bridges. Last week, we began using Knex to bring our ideas to life. At first, using these tiny building pieces posed obstacles in our design process. For example, it was difficult for us to bring our WPBD design into 3 dimensions. Also, it was hard to pick which types of connectors and joints to use. Overall, though, I believe that Knex are a useful tool for learning how to bring ideas to life; whether on a large scale or small.

Therefore I believe that Knex and WPBD should not be compared, but used together. This is because they compliment each other's usefulness. Designing first in the bridge designer and then using Knex should be our process for the next few weeks, and I believe this will be the most efficient way of creating our bridge.

Jordan Banyas Week 5

Transitioning from WPBD to K-NEX is a lot different then I initially thought. The strategy when using WPBD is to keep a moving vehicle supported while it drives across where as the objective of the K-NEX bridge is to have it hold as much dead weight as possible. This week our group has come up with multiple designs we think will be successful. Our goal is to find the weaker areas of each design and improve upon them.

Tuesday, May 1, 2012

Transition

As we move from one design style to another, many new opportunities arise. Unlike before, we are now able to be hands on and see each piece's strength's and weaknesses are. In addition, we can now view our structure in a three dimensional space. This allows us to make modifications inside and on top of the truss. However, there are some drawbacks. The biggest one is that now the revision process after failure is not as simple as WPBD. The time and effort applied into forming a structure has to be applied over and over again after each failure. It is tedious and frustration. Yet, it a sense it is similar to before. We still use the same geometric to distribute force and we definitely use what we learned from WPBD and apply it to our hands on approach.

A2-Carr

The way I designed this bridge was quite standard but I believe it will still perform effectively. It is the shape of a trapezoid to disperse the forces better. I chose to use triangles throughout the bridge to distribute the forces throughout the bridge and not have it deform before failure. As I was advancing through my design process, I had to make many corrections to make sure that the connections of pieces was possible. Also, I desired to not make the connections between the frames too detailed as it would add weight and cost. I had a few drafts but settled with this one. After this process, I learned that if one has to design a bridge, he or she needs to be patient and consider many factors. Multiple drafts will only strengthen the outcome

Bill:

3.375" chord: 21- $31,500

5.00" chord: 14- $ 28,000

360 degree gusset plates: 18- $18,000

Total: $77,500

A2-Jordan Banyas

Throughout the process of designing this bridge, I realized that just the acute triangles would not be long enough to cover the two feet span. because of this my design changed to add two right triangles on the end of my initial design. During the process I learned that the angle constraints are very limited when using basic K-NEX. There is not a whole lot of flexibility in the design process due to there only being a limited number of different pieces.

Tuesday, April 24, 2012

week 4

Since we have been experimenting with West Point Bridge designer, we have noticed many helpful options. Some ways to make the strongest and most cost effective bridge would be to use hollow tubes and to change each of their size. These variables now restrict us less and allow us to be more creative in our designs. I also enjoy the fact that this program also allows us to pick each weak member and make appropriate modifications to it. There are some drawbacks. For example, this program shows a truck moving across so the force is felt in different areas of the design. This conflicts with future designs for our Kinex design will have a fixed load in the middle.

Week Four - Greenwood

Week three was both a very productive and very informative lab. The main focus of the lecture and the rest of the class was the cost efficiency of our bridges. It was made clear to us (through COMP1) that we could not get a contract without proposing a cheap and effective way to create a bridge. Therefore, our group sat down to begin discussing how we would go about slicing the cost of our bridge design. Originally, our pricing was somewhere around $350,000. We considered this to be outrageous, and proceeded to test out different materials and designs. Eventually, we came up with a successful design which brought our pricing to around $215,000. We are not yet finished though, and over the next couple weeks we will implement what we have learned into creating the best design we can.

Throughout this module so far, we have been using West Point Bridge Designer, an engineering simulator program which uses an easy interface to let the user first build a bridge and then test it. The test itself allows a truck to try and drive over the created bridge. It lets you know where the most tension is in the bridge, or if the truck even feels safe enough to cross it at all. This tool has been extremely useful for our team, in that we have been able to send our designs back and forth to each other even outside of lab for examination and critique. It is even a great tool for presenting what I have learned so far. For example, today in English class I was talking to another student about my bridge design and my professor asked me to stand up and talk about the project. He was not being sarcastic, but he was truly interested. I proceeded to show the class my design and its animation, as well as discussing what I have learned so far in the module. WPBD has been an extremely helpful tool inside and outside of lab.

Throughout this module so far, we have been using West Point Bridge Designer, an engineering simulator program which uses an easy interface to let the user first build a bridge and then test it. The test itself allows a truck to try and drive over the created bridge. It lets you know where the most tension is in the bridge, or if the truck even feels safe enough to cross it at all. This tool has been extremely useful for our team, in that we have been able to send our designs back and forth to each other even outside of lab for examination and critique. It is even a great tool for presenting what I have learned so far. For example, today in English class I was talking to another student about my bridge design and my professor asked me to stand up and talk about the project. He was not being sarcastic, but he was truly interested. I proceeded to show the class my design and its animation, as well as discussing what I have learned so far in the module. WPBD has been an extremely helpful tool inside and outside of lab.

Week 4 blog post Jordan Banyas

West Point Bridge Design is a fairly accurate portrayal of what it actually takes to make a bridge. It may not be the most accurate technology out there to create a bridge, but it is a nice introduction. It teach the fundamentals of bridge building to students who do not have a deep background of designing bridges. There are however many downsides of WPBD due to being beginners technology. For example, it has a height limit that is unrealistic to a bridge design. Another flaw is the inability to make a suspension bridge and even to put joints in certain points. Joints are only able to be put in on a fixed grid system which does not allow for much creativity. There are only a few designs that optimize the the forces of the truck driving across the bridge.

This week I was able to shave off close to ten thousand dollars on our design we made in class. Our hope as a group is to improve upon our current design as well as continue to try and come up with a new innovative way to support the truck without spending as much money as we are spending now. Currently, my design costs us $215,858.44. we hope to make improvements this week.

This week I was able to shave off close to ten thousand dollars on our design we made in class. Our hope as a group is to improve upon our current design as well as continue to try and come up with a new innovative way to support the truck without spending as much money as we are spending now. Currently, my design costs us $215,858.44. we hope to make improvements this week.

Wednesday, April 18, 2012

Week 3 and Questions

This week our team worked on our first designs using west point bridge designer. Although they were similar in theory, the way we created them and the prices were all much different. In the next week and in lab, we will need to make the final touches on these designs and create a cheap and effective truss bridge. To accomplish that, teamwork will be required and all of our ideas will need to be utilized.

In lab this week we have the engineering librarian coming, and we have created a few questions for him:

1. Is there much research to be done on bridge engineering here at Drexel?

2. What kind of books on bridges should we look for?

3. Who are some famous bridge builders and what bridges did they create?

In lab this week we have the engineering librarian coming, and we have created a few questions for him:

1. Is there much research to be done on bridge engineering here at Drexel?

2. What kind of books on bridges should we look for?

3. Who are some famous bridge builders and what bridges did they create?

Tuesday, April 17, 2012

A1-Banyas

Sketch of Bridge Design

Bridge in Action

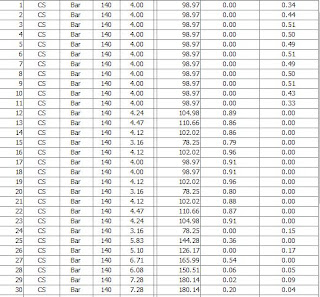

Data Table of Forces

Initially I had a standard cross section in block formation that seemed to work very well but was very costly. The new design I came up with uses triangles as apposed to cross sections. By varying the angles I was able to balance the bridge is safe for the truck to drive over. This design only costs $343,413 and meets all of the requirements of building a safe bridge. I believe my bridge design could use work as there is still one beam that has a stress level over .95. From tinkering around with the bridge design technology I learned that it is very important to look at how much weight is put on the joints by hanging beam supports from them.

A1-Carr

The design for the present bridge had to support a moving object, the truck. The difference that I had to account for was that the force being applied was different over time. Therefore there had to be a constant patter throughout the bridge and it had to be symmetrical. The use of triangles is evident in the design and they distribute the force appropriately. As the truck moved across the bridge the top beams recieved the most stress but held strong. One thing that could be improved is the strength of the top supports and to lower the weight of the material altogether. The estimated cost for this bridge is about 350,000 dollars. I do not forsee our group following this design because in the competition, the weight will remain stationary. Therefore, I predict that the new design, using kinects, will distribute the force from the center. I learned that to design a brige for a moving object is much more difficult than designing one for a stationary one.

A1- Greenwood

For this first design, I decided to keep a simple truss layout that would be cheap and effective. The top of the bridge would slowly elevate until a central height was established, and underneath would be several trusses that jut out triangularly. Considering this first week's assignment was to establish a design the team could build on and improve, I believed the simplest would also be the best. Here are the images from my design as well as the stress tables and price.

Above is the 2d design of my simple truss bridge.

Above is the 2d design of my simple truss bridge.

Above is the 3d design of my bridge with a truck on it.

This is a picture of the stress table feature in WPBD.

During the design process of this bridge, the actual design changed many times. For example, from my first design I added more joints and more trusses, considering the stress points in the joints were much greater when there were less. Also, I made the max height of the bridge lower to make the flow of force through it more uniform. Although adding more joints and trusses increased the price, it also gave me a working design.

Estimated Price : $347,715

This price is high as of right now, but I am confident it can be lowered. There seem to be too many large trusses that need to be redesigned so that they are stronger and more capable of handling stress.

From this initial assignment, I have learned that simple designs can actually be successful and work. I also believe that my knowledge can only increase so that I may be able to successfully build cheaper, stronger designs.

Tuesday, April 10, 2012

This blog will be used to keep track of our group's efforts in completeing the objective. It is extremely important to see how the group advances over a period in time and to keep a reference of this progress. This week , we will begin work on the project assigned and brainstorm ways to most successfully complete it. A collaborative effort will yield an effective plan of action or the labs to come.

Teamwork - John Greenwood

At the end of week one, it becomes obvious that the emphasis on this module will be working as a team. Not only will we be competing against the other teams in the section, but we will also be submitting our bridge designs to a local contest. Due to this, I believe I will need to take initiative and do my part. If one of us starts to fall behind, it is the other two of our jobs' to not only help the weak link but also to motivate him to step up. We all need the grades and I believe if we accomplish the tasks laid before us in the coming weeks we will see great improvement in our academic abilities.

The website "Teamwork" by Professor Mitchell recommends using each team members ideas thoroughly and often. It also encourages using the team's differences among each other to create a more unique approach to the engineering design process. Since the design process is the most important aspect of this course, this seems like a logical thing to pay attention to. Over the next couple weeks, our teams goal should be to start our research and try and come up with a fresh and innovative bridge design. We need to bring something new to the table while also showing our ability to work together as a team. Nothing can be accomplished through selfishness. Since realizing this is the largest obstacle we will need to overcome, this is the first of many steps our group will need to take in order to complete this module.

-John Greenwood

The website "Teamwork" by Professor Mitchell recommends using each team members ideas thoroughly and often. It also encourages using the team's differences among each other to create a more unique approach to the engineering design process. Since the design process is the most important aspect of this course, this seems like a logical thing to pay attention to. Over the next couple weeks, our teams goal should be to start our research and try and come up with a fresh and innovative bridge design. We need to bring something new to the table while also showing our ability to work together as a team. Nothing can be accomplished through selfishness. Since realizing this is the largest obstacle we will need to overcome, this is the first of many steps our group will need to take in order to complete this module.

-John Greenwood

Jordan Banyas Blog Post 1

In this class our assignment is to build

a bridge that is both the strongest as well as the least costly. In order to

obtain this goal, Kevin, Jake and I must work together as a team. The teamwork aspect of the creation of this

bridge is one of the most integral pieces of the project. We all have the same

motivations to do well in this project. Besides just getting a good grade in

the class, Kevin and I are currently Civil Engineering major’s and are eagerly

awaiting the knowledge that comes along with designing a support structure such

as a bridge. Although the bridge is only made out of K’NEX, the supports

structures we learn about in this class can be translated into a real life scenario’s

and give us real world skills to set us apart from other hopeful Civil

Engineering applicants. I feel teamwork is important because if one learns the ability

to work as a team, he then learns broadens his horizon on his own knowledge. Not

only are one person’s ideas going into the project, but now all three teammates

are working together to pull out the best possible ideas to make the project as

successful as possible.

-Jordan Banyas

Week One - Teamwork (Group)

During week one's lab, the basics of bridge building and the dynamics of civil engineering were discussed. On top of this, the course expectations were laid out. We observed many modern bridge designs before creating our teams. The most obvious challenge to be overcome in the next few weeks will be working as a single unit to establish the most successful design. This requires something which in theory is simple: teamwork.

According to Professor Mitchell's website, teamwork is an "organized process that requires concentration on people as well as product". Therefore, during this module our group must not only focus on our task, but also on strengthening our effectiveness as a team. This is just as important as our assignments because in the real world, almost anything can be achieved when more than one mind is put to a single task. Here in engineering 103, our team must compliment each other's skills, as well as welcoming any differences that may arise. By the end of these ten long weeks, this bridge building group needs to work like a well oiled machine with many different gears.

Next week we need to begin our research and start creating initial designs. Nothing will be set in stone, but the research will not do itself, and we can not afford to fall behind.

-Three Pikes on a Bridge

(John Greenwood, Jordan Banyas, Kevin Carr)

According to Professor Mitchell's website, teamwork is an "organized process that requires concentration on people as well as product". Therefore, during this module our group must not only focus on our task, but also on strengthening our effectiveness as a team. This is just as important as our assignments because in the real world, almost anything can be achieved when more than one mind is put to a single task. Here in engineering 103, our team must compliment each other's skills, as well as welcoming any differences that may arise. By the end of these ten long weeks, this bridge building group needs to work like a well oiled machine with many different gears.

Next week we need to begin our research and start creating initial designs. Nothing will be set in stone, but the research will not do itself, and we can not afford to fall behind.

-Three Pikes on a Bridge

(John Greenwood, Jordan Banyas, Kevin Carr)

Subscribe to:

Comments (Atom)